Etching pot water-based super ceramic durable non-stick coating

The Zheming etching pot special water-based super durable non-stick ceramic coating is a product with excellent super strong and long-lasting non-stick properties, and an extended service life. The product has outstanding scratch and wear resistance, with strong non-stick performance after washing with detergents and high temperatures. This coating addresses the shortcomings of existing ceramic coatings for cookware in this functionality, showcasing its breakthrough innovative technical highlights. The application of independently developed new materials in the product ensures a high technical starting point while maintaining a high cost-performance ratio. In various performance aspects, it far exceeds other etching pot ceramic coatings.

- Product Description

-

Etching pot water-based super ceramic durable non-stick coating

Through continuous product research and formula upgrades, a special coating for etching pots has been developed. This water-based ceramic durable non-stick coating is a new type of coating that combines the advantages of organic and inorganic materials, featuring high temperature resistance, high hardness and wear resistance, acid and alkali corrosion resistance, super strong and durable non-stick properties, and environmental friendliness.

Etching pot performance test report

Test item: Coating wear resistance - metal needle (tiger claw) - internal coating

Reference standard: Y0762 customer testing standard

Testing method:1. Install the tiger claw pen core around the cooking surface of the pot/skillet, applying a force of 160±10g.

2. Add an appropriate amount of oil to the pot/skillet to cover the bottom surface.

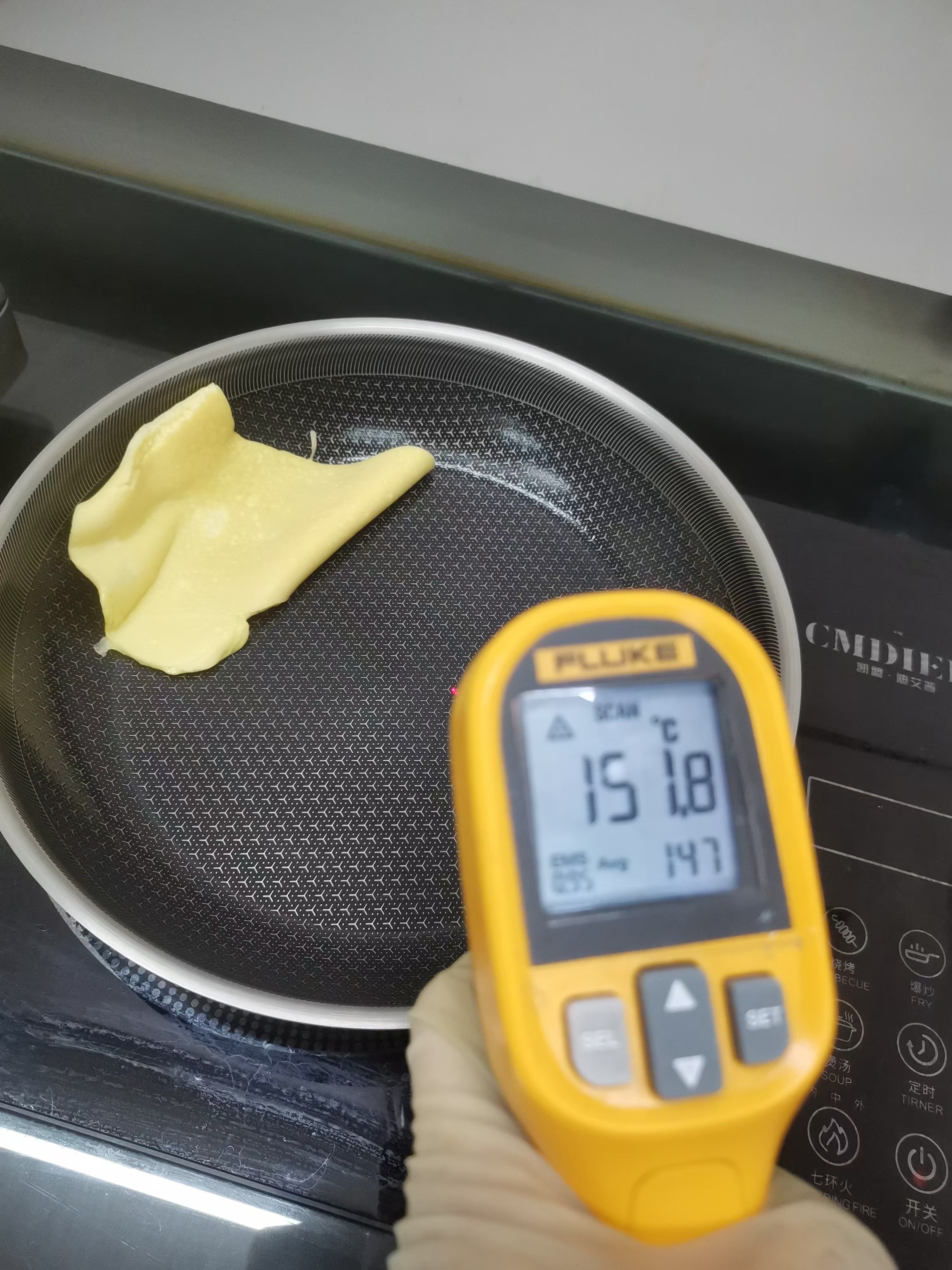

3. Heat the surface peanut oil to 200℃.

4. Turn on the device and adjust the speed to 40 RPM.

5. Conduct an egg frying test every 500 cycles, recording the number of failed tests.

Test result: Referencing 4000 cycles, the substrate was not exposed, and the egg frying did not fail.

Test item: Scouring pad wear resistance - 3M7447C - internal coating

Reference standard: Y0762 customer testing standardTesting method:

Scouring pad diameter: 5cm,

Load: 3kg,

Wet grinding: Stroke of the grinding head: 10cm;

Movement speed: 40rpm;

Scouring pad type: 3M, 7447C.

Replace with a new scouring pad every 1000 cycles and conduct an egg frying test.

Test result: Referencing 60000 cycles, the bottom was not exposed, and the egg frying did not fail.

Test item: Scouring pad wear resistance (3M, Blue) - internal coating 5

Reference standard: Y0762 customer testing standard

Testing method:Scouring pad diameter: 5cm,

Load: 3kg,

Wet grinding: Stroke of the grinding head: 10cm

Movement speed: 40rpm

Scouring pad type: 3M, Blue. Replace with a new scouring pad every 1000 cycles and conduct an egg frying test.

Test result: The test reached 100,000 cycles without exposing the bottom, and the egg frying test did not fail.

Test item: Scouring pad wear resistance (3M, Green) - internal coating

Reference standard: Y0762 customer testing standardTesting method:

Scouring pad diameter: 5cm,

Load: 3kg,

Wet grinding: Stroke of the grinding head: 10cm

Movement speed: 40rpm

Scouring pad type: 3M, Green.

Replace with a new scouring pad every 1000 cycles and conduct an egg frying test.

Test result: Referencing 60000 cycles, the bottom was not exposed, and the egg frying did not fail.

Test item: Thermal shock test - internal coating

Reference standard: Y0762 customer testing standard

Testing method: Place the skillet in a 300℃ oven for 30 minutes, then place it in 20℃ room temperature water for 5 minutes (testing one cycle)Requirements: A total of 100 cycles of testing: Conduct surface hardness and coating adhesion tests before and after the thermal shock test, with no failures.

Test result: Qualified, the test reached 100 cycles without failure.

Test item: Thermal shock test (egg non-stick) - internal coating

Reference standard: Y0762 customer testing standard

Testing method:

1. Place the pot in a 600°F oven for 30 minutes.

2. Remove the pot, let it sit for 5 minutes, then rapidly cool the pot with water at room temperature.

3. Conduct the egg test and score.

4. Repeat steps 1-3 for 25 cycles.Test result: Qualified, 35 cycles of egg frying did not fail.

Test item: Chemical resistance (egg non-stick) - internal coating

Reference standard: Y0762 customer testing standard

Testing method:1. 2% detergent, water temperature 85℃/1 hour.

2. Conduct an egg frying test (cracking the egg) for each cycle.

3. Conduct the egg test and score.

4. Repeat steps 1-3 for 20 cycles.Test result: Qualified, 20 cycles without failure, 35 cycles of egg frying failed.

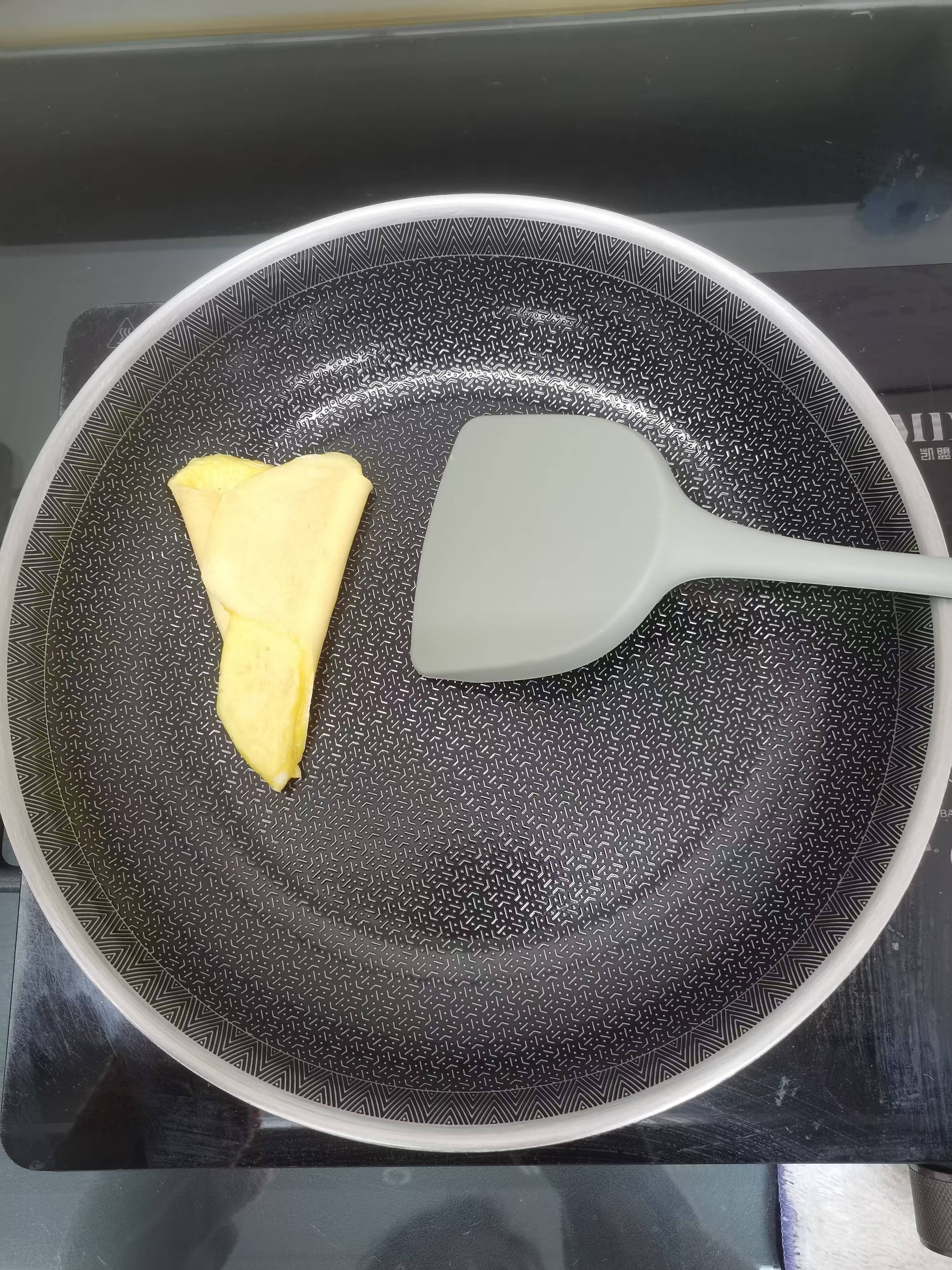

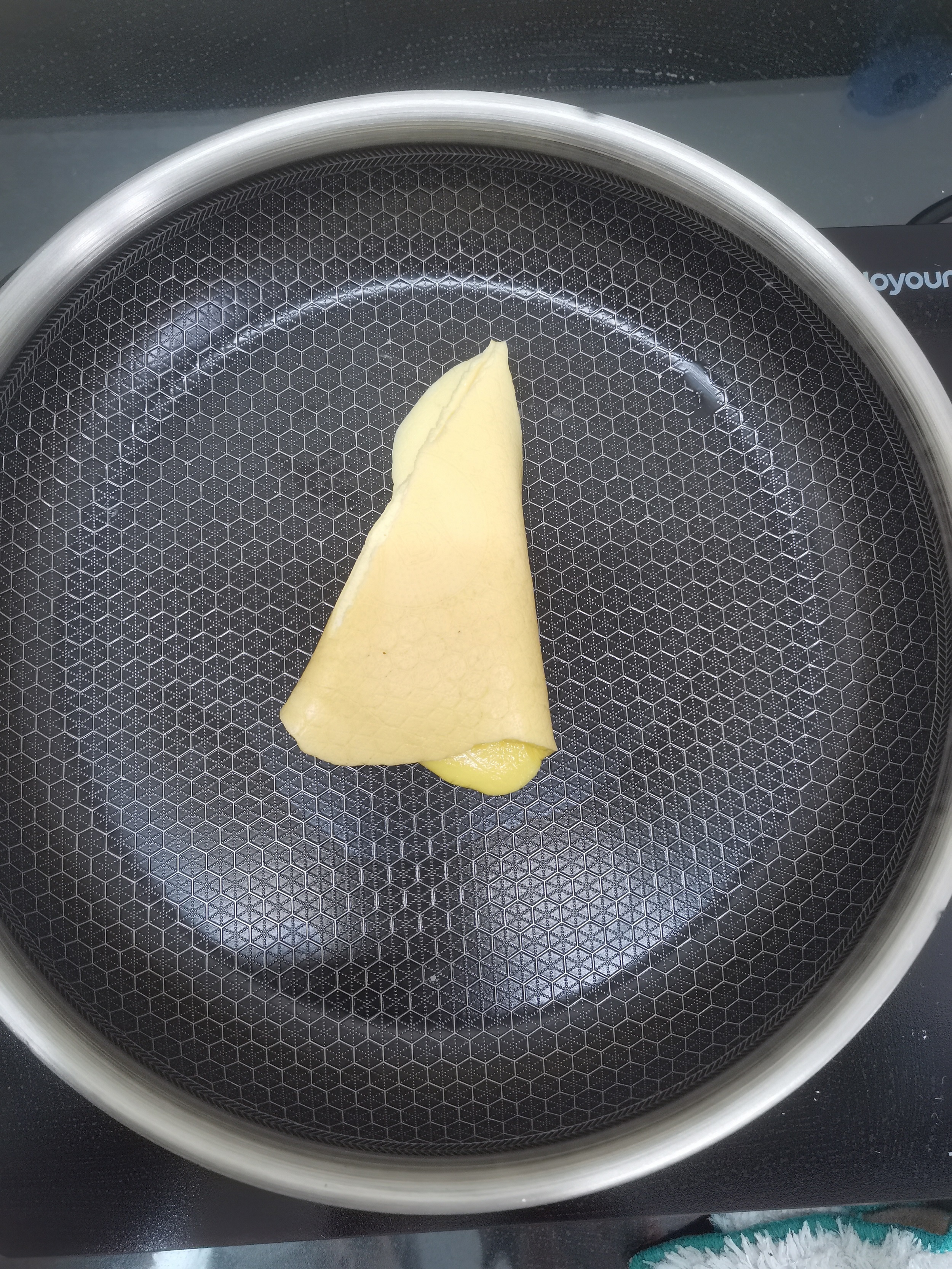

Test item: Frozen egg test - internal coating

Reference standard: Y0762 customer testing standard

Testing method:

1. Place the frying pan on the stove, set the stove to medium heat, and preheat for 4 minutes or until the surface of the frying pan reaches 350°F.

2. Crack the egg into the pan, cook for 1 minute and 30 seconds, until most of the egg white is set (Joyoung ceramic electric stove: 400W power).

3. Use a spatula to scrape around the edge of the egg, flip the egg. Cook for another 1 minute and 30 seconds on the other side.

4. The egg should release easily, with nothing sticking around the edges or in the middle.

5. After cooking, take a photo of the egg in the pan.Test result: Qualified, the egg can be released from the pan.

Product Consulting